What is resinous flooring?

Resinous flooring is not a term you see that often. Most often people will talk about having an epoxy installed on their floor when in actuality, an epoxy may be only a part of the coating or might not be used at all. Epoxies are a specific type of resinous flooring. The general term “resinous flooring” can include not only epoxies but also polyurethanes, acrylics, and vinyl esters, to name a few.

So what exactly is resinous flooring? If you look up the general term “resinous materials” online, it will say that they are “cross-linked polymeric materials”. Unless you have a background in chemistry, that might not mean much! Suffice it to say that when you mix the components of a resinous floor system they chemically react to form a new material. In each case the chemical make-up of the resinous flooring products give them specific characteristics that will fill a variety of flooring needs.

Traditionally resinous floors are used in facilities in the automotive, food/beverage, pharmaceutical and R&D markets. More recently the use of resinous flooring has expanded into restaurants, stadiums, and educational, recreational, and commercial facilities.

Why use resinous flooring?

Resinous coatings have a better life cycle than carpet, tile and sheet goods. They are seamless, non-porous, easily cleaned, will not harbor dirt or bacteria, and naturally resist microbial and mold growth. Unlike all other forms of floor covering materials, resinous flooring can be designed to have a wide range of specific physical properties to solve the problems that a commercial or industrial floor will face. In addition, resinous coatings can extend the useful life of concrete. Old, beat up floors can be brought back to life instead of removed and replaced.

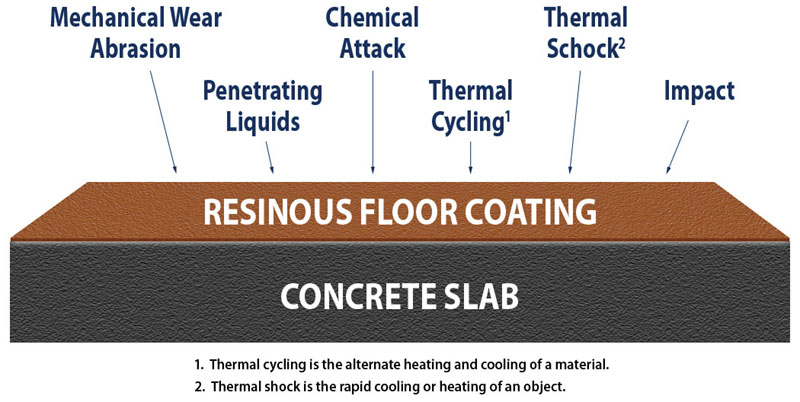

The physical properties such as the thickness, the type of material used, and the aggregates added to the resins will enable the surface coating to protect the concrete floor. What are the types of problems a resinous coating can be designed to mitigate? The diagram below shows a few of the most common problems that an industrial or commercial concrete floor might face.

Protecting Your Concrete Floor

Characteristics of resinous floors

As you can see, properly designed resinous floors can protect your floor from a wide range of problems presented by various commercial and industrial operations.

Other general characteristics of resinous floors that have to be considered when designing a floor are the slip resistance and cleanability. A slip resistant floor does not necessarily have to be rough. A resinous floor’s surface texture can be adjusted to have the profile that best suits the use of the floor. Often even though a floor has a relatively smooth surface, the floor can have a slip resistance high enough to be considered a high traction floor per ANSI B101 standards.

Fortunately no matter how rough or smooth a floor is it can be cleaned by using the proper cleaning materials and methods. The nature of the resinous floor installed dictates how the floor should be maintained. It is important when a resinous floor is installed that the contractor work with the owner to develop a plan for long term maintenance of the floor.

Moisture Content

Even with all of this versatility there are some limitations in terms of the application of resinous flooring. For most materials the moisture content of the concrete slab to which the resinous floor is applied cannot be more than 4%. There are both moisture tolerant and moisture insensitive materials that can be utilized to help eliminate or mitigate this problem. There could be budgetary or other limitations and if the moisture content is too high a resinous floor should not be applied. It is advisable that if a site is believed to have a high water table or moisture laden soil that a vapor barrier directly below the slab be specified with very detailed installation requirements. This can often reduce the transmission of water up through the slab to tolerable limits.

Which type of resinous floor do you need?

As you have seen, resinous flooring can help to protect concrete floors in a wide range of applications. The one thing that all of the applications have in common is that only the right resinous floor system will provide a safe, hygienic, and profitable working environment.

Have any questions about the type of resinous floor that is right for your flooring needs; call our office at 716-831-7091.

About the author

Jim Guido is the editor and a contributing writer to The Concrete Floor Report.